Proportional Solenoid Valves

The key component of the ventilator is a proportional solenoid valve. A PSV, an input pressure sensor or regulator, and a microcontroller gives a viable minimum ventilator. The valve needs to support a flow rate of 50L/min (833mL/s) – 100L/min would be preferred. Multiple small valves can be used in parallel if a single large valve is not available. Valves I have identified are in the table below. There are clearly many more:

| Part | NoFlow Rate (L/min) | Max Pressure (PSI) |

|---|---|---|

| SMC PVQ31-6G-40-01 | 70 | 20 |

| SMC PVQ31-6G-23-01 | 100 | 50 |

| SMC PVQ31-6G-16-01 | 100 | 100 |

| EV-P-10-25A0-V | 25 | 100 |

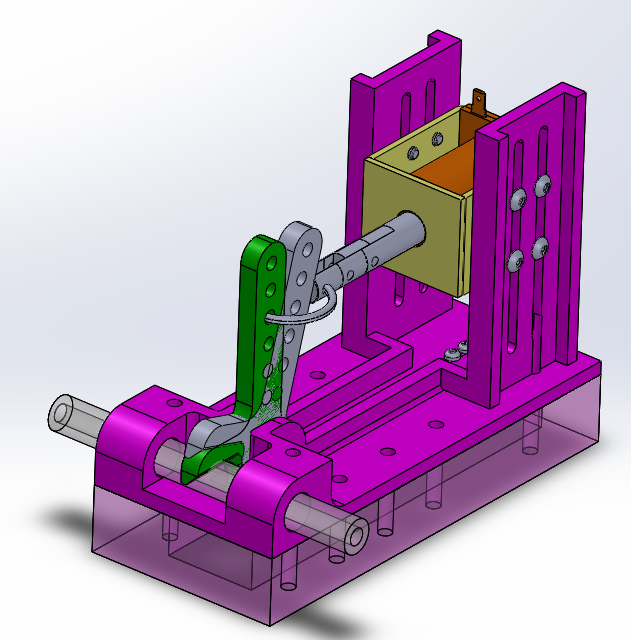

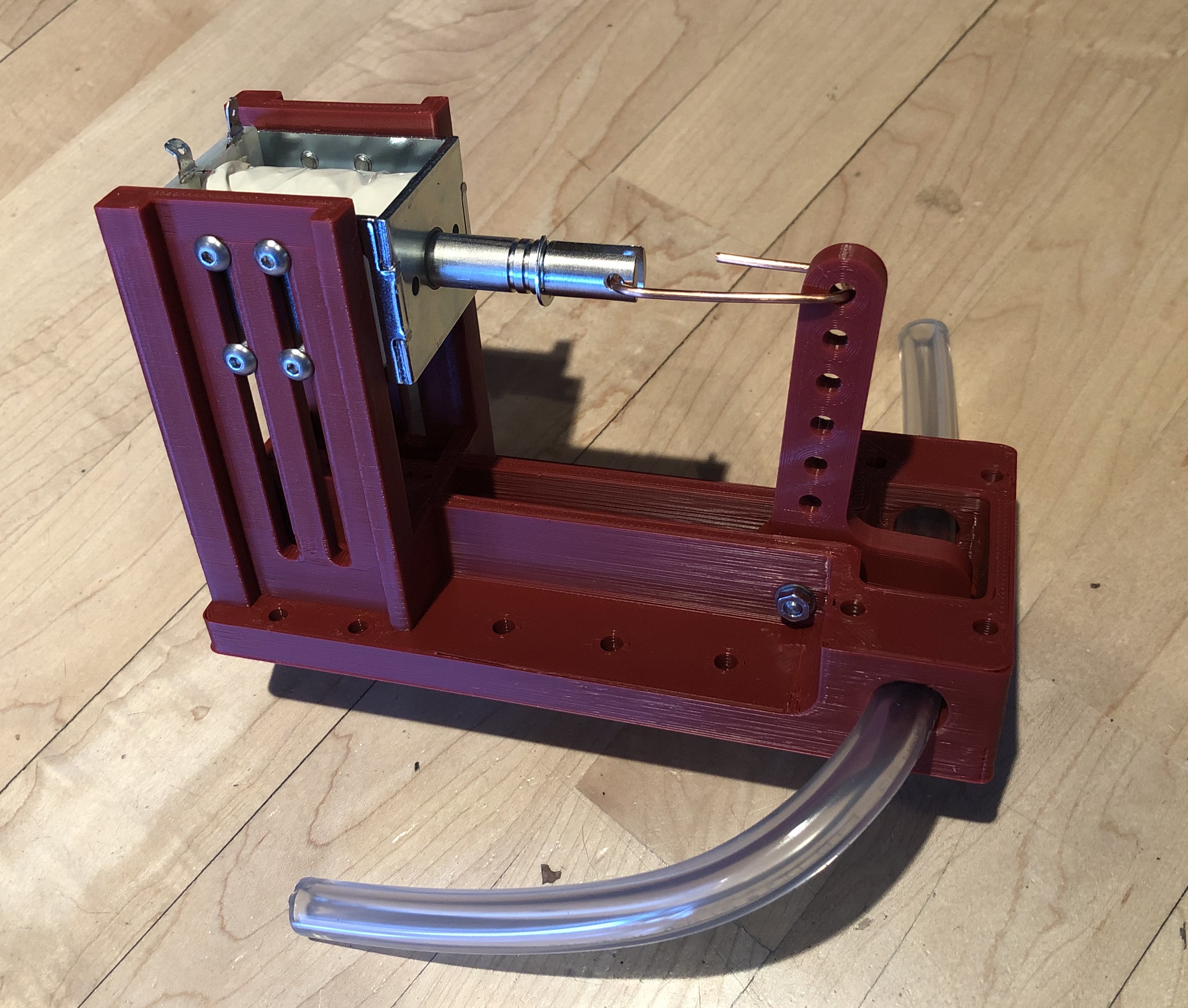

To mitigate against the risk of supplying solenoid valves, we have designed an open-source “pinch valve”. A spring holds a Tygon tube “pinched” in the closed position. As a solenoid is energized, it pulls against the spring opeining the tube and controlling airflow. A solid-works model is shown in Figure 8, and a photo of a prototype in Figure 9. Solenoids are readily available, so only the valve itself need be printed. The design is suitable for injection molding and so can be fabricated inexpensively in large quantities.

Figure 8: Solidworks model of open-source pinch valve. Design by Paul Karplus.

Flow Sensors

MEMs mass flow sensors are made by Honeywell, Sensirion, Siargo, and others. These are available in 50L/min and 100L/min ranges. Automotive mass flow sensors could in theory be adapted, but out of the box have flow ranges that are 10-100x too high 1000s of L/min.

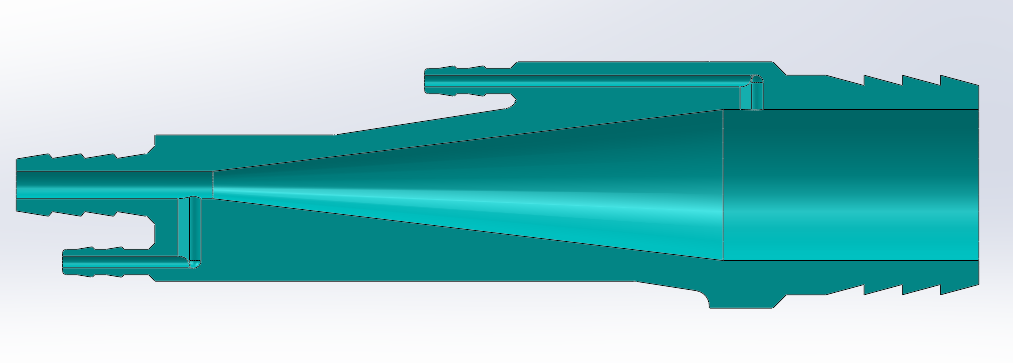

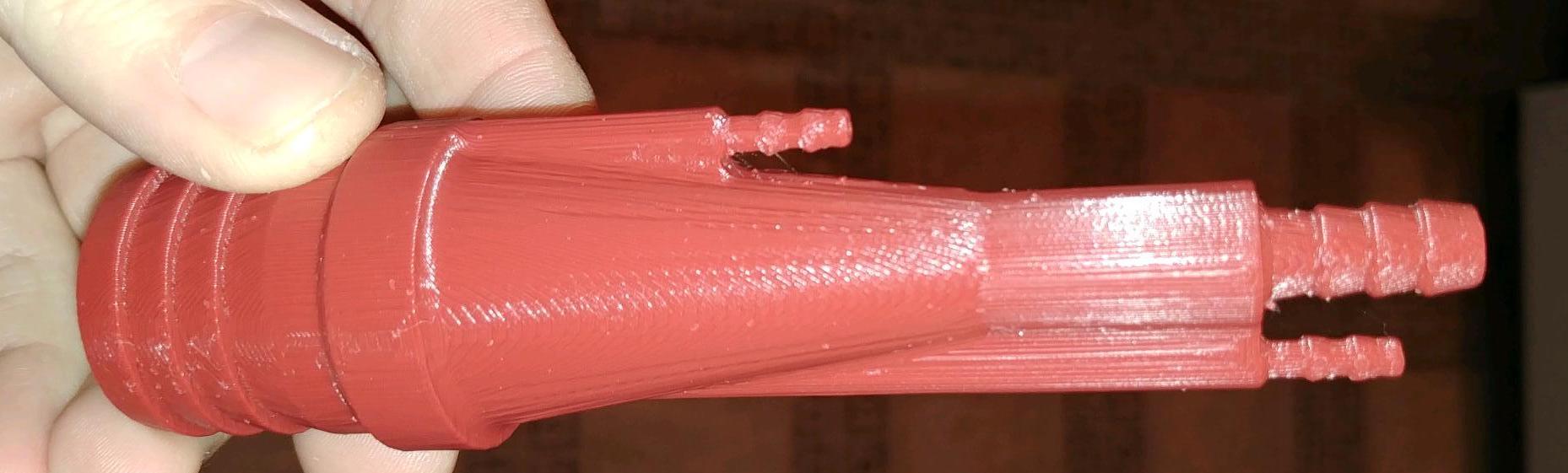

To mitigate against flow-sensor supply issues, we have designed an open-source Venturi-tube that converts flow to differential pressure. A differential pressure sensor can then be used to give an electronic reading of flow. Figures 10 and 11 show the open-source Venturi-tube.

Figure 10: Solidworks model of open-source pinch valve. Design by Paul Karplus.

Figure 11: Solidworks model of open-source pinch valve. Design by Paul Karplus.

Other options include a hot-wire anemometer (may be a challenge at these low flow rates) or a strain gauge on a vane.

Pressure Sensors

An input pressure sensor (0-30PSI) is required for the ventilator to work open-loop without a pressure regulator. An output pressure sensor (0-1PSI) is useful to set a maximum output pressure (less than the safety valve) and to monitor pressure. Both types are generally available from multiple manufacturers. A differential pressure sensor with a range of 1-2kPa is needed to read the differential pressure across the Venturi tube.

Pressure Regulators

An input pressure regulator can be used instead of a pressure sensor to enable open-loop operation. The prototype in Figure 3 uses a regulator intended for use with air. The manufacturer has confirmed that this will work with an air/O2 mix or pure O2.